The brushless DC motor market is at the forefront due to rapid automation transformation. These motors are rapidly becoming an essential component of industries such as manufacturing and construction because they offer several benefits that boost output, lower costs, and improve overall performance. This article looks at these industries’ global significance, investment opportunities, and new developments, as well as how BLDC motors are transforming them.

What Are Brushless DC Motors?

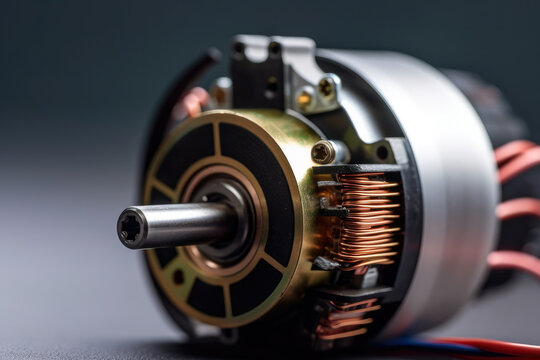

In contrast to conventional brushed motors, brushless DC (BLDC) motors are electric motors that run without brushes. These motors have a higher efficiency and a longer lifespan since they use electronic controllers to regulate the current. The primary distinction between brushed and BLDC motors is the lack of mechanical brushes, which lowers wear and friction and results in more dependable operation.

Advantages of Brushless DC Motors

The key benefits of BLDC motors are their low maintenance needs, silent operation, and exceptional energy economy. These motors are perfect for a variety of automation applications because they provide accurate control, high torque, and improved heat dissipation. These characteristics help manufacturing and construction run more smoothly, save money, and increase productivity.

Role of Brushless DC Motor Market in Manufacturing Automation

Manufacturing is one of the sectors most affected by automation in recent decades. As Industry 4.0 gains traction, businesses are adopting cutting-edge technologies to enhance their operations. Because they power robots, conveyors, and other automated systems, BLDC motors have taken center stage in this transition.

Improved Production Process Efficiency

By providing great torque at low speeds and using less energy, BLDC motors contribute to increased manufacturing energy efficiency. Their capacity to give exact control makes better management of production processes, waste reduction, and output optimization possible. For instance, BLDC motors are increasingly used in robots and automated production lines to enable quicker and more precise assembly.

Low Maintenance and Longer Lifespan

Another important advantage in manufacturing is BLDC motors’ low maintenance requirements. Conventional brush motors need to be replaced frequently since they deteriorate over time. However, because BLDC motors have fewer moving components, they are less likely to experience mechanical failure and have a longer operational lifespan. This is especially helpful in settings with high demand because downtime can be expensive.

Brushless DC Motors in Construction Automation

Automation is also bringing about major changes in the construction sector, and BLDC motors are essential to this development. They are at the core of many cutting-edge systems, from advanced machinery to driverless cars.

Enhanced Precision and Control in Construction Equipment

For construction equipment such as cranes, excavators, and drilling machines to finish jobs effectively, precise control and great performance are necessary. BLDC motors supply the torque and control required to maximize the performance of these machines. In addition, they facilitate smoother motions, which lessen vibrations and wear on the equipment, increasing safety and lowering maintenance expenses.

Integration with Autonomous Construction Vehicles

Autonomous cars have become more popular in the construction industry in recent years. These vehicles are best powered by BLDC motors, which operate quietly, effectively, and dependably. With the use of BLDC motors, these vehicles can move goods, dig trenches, and carry out other necessary duties without much assistance from humans, saving money on labor costs and increasing output.

Trends in Construction Automation

BLDC motors are becoming increasingly popular in the construction industry, especially in fields such as automated material handling systems, drones for surveying, and autonomous construction equipment. The adoption of BLDC-powered autonomous robots to perform jobs such as welding and bricklaying is a significant trend that lowers human labor costs while enhancing safety.

A key component of the automation revolution in construction and industry is expected to be brushless DC motors. Because of their effectiveness, low maintenance needs, and superior performance are becoming the preferred option for businesses trying to cut expenses and boost productivity. The need for BLDC motors will only increase as the global automation market expands, providing a wealth of opportunity for both investors and companies. Industries may increase efficiency, boost accuracy, and save significant money by incorporating these cutting-edge motors into construction equipment and production lines. Brushless DC motor market is expected to soar to new heights and will set the standard for automation in the future.