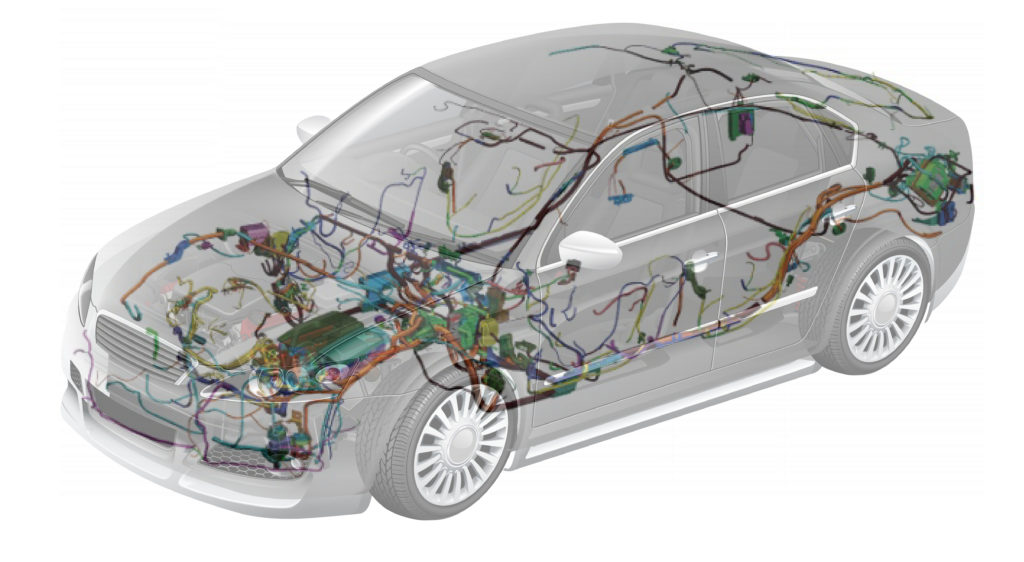

The automotive industry is undergoing a seismic transformation, driven by the rapid adoption of electric vehicles (EVs), advanced driver-assistance systems (ADAS), and connected car technologies. At the heart of this transformation lies an often-overlooked component, such as the wiring harness. This vital network of wires, connectors, terminals, and cables serves as the nervous system of modern vehicles, facilitating power distribution and data transmission. This article highlights the growth drivers, opportunities, and key trends shaping the automotive wiring harness industry.

Key Growth Drivers in the Wiring Harness Industry

The Rise of Electric Vehicles (EVs)

The shift toward battery electric vehicles (BEVs) and plug-in hybrid electric vehicles (PHEVs) is revolutionizing the wiring harness market. Unlike traditional internal combustion engine (ICE) vehicles, the average EV requires 30-50% more wiring than ICE vehicles. EVs demand for wiring is significantly more due to their reliance on high-voltage batteries, charging systems, and advanced powertrains. However, manufacturers of high-voltage wiring systems, connectors, and terminals stand to benefit immensely from this growing demand.

Advanced Driver-Assistance Systems (ADAS)

Features like lane-keeping assistance, adaptive cruise control, and collision avoidance are becoming standard in modern vehicles. These systems rely on low-latency communication between cameras, sensors, and control units, all interconnected by a robust wiring harness. The integration of Ethernet cables in wiring harnesses is gaining traction to support high-speed data transfer for ADAS functionality. Ensuring the durability of wires in harsh environments like extreme temperatures and vibrations.

Connectivity and IoT in Cars

With the rise of connected cars, wiring harnesses must handle data from infotainment systems, over-the-air (OTA) updates, and telematics. This has led to the adoption of lightweight, compact, and durable wiring solutions to optimize vehicle performance without compromising connectivity.

Applications of Wiring Harnesses in Automobiles

The increasing complexity of these systems is driving demand for specialized wiring harness designs that prioritize safety, performance, and cost-effectiveness. Wiring harnesses are indispensable across various automotive systems. Following are some major applications such as:

- Body Wiring: Controls interior and exterior lighting, power windows, and dashboard instrumentation.

- Chassis Wiring: Facilitates ABS, suspension systems, and braking mechanisms.

- Engine Wiring: Connects components like ignition systems, alternators, and fuel injectors.

- HVAC Wiring: Powers heating, ventilation, and air conditioning units for optimal cabin comfort.

- Sensor Integration: Links critical sensors for tire pressure monitoring, temperature regulation, and ADAS features.

Opportunities in Wiring Harnesses

- Lightweight Materials

Automakers are turning to lightweight materials like aluminum wires to reduce vehicle weight and improve energy efficiency. These materials are particularly beneficial for EVs, where battery weight is already a concern.

- High-voltage Systems

With the proliferation of EVs, high-voltage wiring systems are essential to connect batteries, inverters, and motors. These systems require robust insulation to ensure safety and efficiency.

- Modular Wiring Harnesses

Modular designs allow for easy integration of new features, such as ADAS and infotainment systems, without significant modifications to the existing wiring infrastructure.

- Complexity Management

As vehicles become more sophisticated, managing the complexity of wiring systems poses a significant challenge. This creates an opportunity for automation and AI-driven design tools to streamline development.

“In April, Kia issued a recall for 95 Sorento SUVs from the 2024 model year because of incorrectly assembled wire harnesses that may cause a malfunction in the power steering system.”

- Cost Optimization

Balancing quality and cost is critical, especially as raw material prices fluctuate. Companies investing in innovative manufacturing techniques, such as 3D printing for harness components, are likely to gain a competitive edge.

- Sustainability Practices

Marketers must find sustainable and eco-friendly wiring harnesses system made from recyclable materials, that are gaining traction as automakers strive to meet sustainability goals.

- Regional Growth

Asia-Pacific is known as a hub for EV production and adoption, driving demand for wiring harnesses. Similarly, North America and Europe’s growing emphasis on ADAS and connectivity features boost market potential.

Future Outlook

The global automotive wiring harness market size is expected to reach USD 63.0 billion by 2030, this growth is fueled by advancements in EVs, ADAS, and connected car technologies. As vehicles become smarter and greener, the demand for reliable, high-performance wiring systems will only intensify. The automotive wiring harness industry may not grab headlines like self-driving cars or EV batteries, but it is undeniably the backbone of modern automotive innovation. There are immense growth opportunities on the horizon in harness wiring in the automotive sector is set to play a pivotal role in shaping the future of mobility.

Key Takeaways for Industry Stakeholders:

- Invest in R&D of lightweight, high-voltage, and modular designs.

- Collaborate with original equipment manufacturers in automotive can drive innovation and ensure market relevancy

- Strive for sustainable development of eco-friendly products can enhance brand value and meet regulatory requirements.